Argo Aim Corrector

The Argo Aim Corrector was the comprehensive fire control solution proposed by Arthur Pollen for use by the Royal Navy. It was not adopted for service use, although subcomponents were deployed as part of fire control solutions generally centered about the Dreyer Fire Control Table.

The Argo Aim Correction System was a family of devices intended to fully address the problem of engaging one moving ship at great range from another. It was centered on a well-integrated "Clock" which comprised many automated functions to model the evolving geometry of the firing solution. This clock was to be informed of enemy bearings and ranges continuously by a stabilized coincidence rangefinder mounting aloft, and a continuous true-course track of the two vessels would be automatically traced by the exquisite Argo Plotter. And, as advanced and ambitious as this system was, it was deployed only in pieces and haltingly throughout the Royal Navy.

Let's focus on the components in turn, from input, to visualization, to calculation, and discuss the components as the inventor, Arthur Pollen envisioned their use.

Argo Rangefinder

The Argo system relied upon a single optical instrument to supply simultaneous and continual estimates of the target ship's range and bearing. While rangefinders were in growing use in many navies, Arthur Pollen found that it was difficult for operators to simultaneously address themselves to the challenge of taking range estimates while keeping the instrument on in yaw (bearing). While others solved this problem by making two-man instruments where one would train the unit while the second ranged, Pollen added the input of a gyrocompass to allow the mounting to automatically track the object when one's own ship yawed about.

At the time it was created, it was expedient to employ torpedo gyros which were propelled and refreshed by air blasts. It beras mentioning that these images are created from preliminary designs, and that later production units involved a second crewman to manage the training angle, and so this may not have tremendous historical accuracy when considering actions of WW-I.

This innovation reduced the workload on the operator and reduced the need to train the mounting to that required to account for changes in the object's compass bearing. The rangefinder was a Barr and Stroud F.Q. 2, 9 feet in base length.

Like other rangefinders of the Royal Navy, the range on this one was continually passed over wires by an asynchronous electrical data transmitter. A similar transmitter conveyed the bearing. When a foot-trigger was depressed, an additional signal would bless the currently indicated range and bearing as legitimate.

In Arthur Pollen's preferred vision of a purely Argo-equipped ship, the pressure of the foot switch would cause the enemy pencil to touch the paper of the Argo Plotter at the scaled range and bearing being signalled.

Argo Plotter

The Argo system favored true-course plotting (as opposed to time-and-bearing plotting, as the Dreyer system employed). True-course plotting is the most straight-forward, in that it simply means, "draw a track chart of our ship's and the enemy ship's courses". Essentially, this means, "plot out the battle". The clarity of the representation as an historical record of the action is clear, but to this writer its utility in advancing its drawer to the goal of hitting the target is suspect.

The plotter worked by placing a rigid drawing board underneath a set of rollers with a pencil between them. This pencil's mark on the board represented own ship's course, and the rollers, by their synchronous or independent movements could cause the card to translate or rotate or any combination of those motions to allow own ship to turn and steam at any rate. A second pencil whose distance from the first could be altered along a worm screw traced the course of the enemy ship. It was by the clever driving of the rollers and the rate at which the enemy ship was moved toward or away from the rollers that any conceivable pair of paths could be described on the drawing card. The only issue would arise if one or the other ship ran off the board, at which time it would be flipped over, manually repositioned to give more room, or replaced.

The Argo Plotter was not considered a success although it was eventually made to work fairly reliably. My personal view is that someone eventually asked themselves, "how does having this drawing help us in any way, shape or form?"

Argo Clock

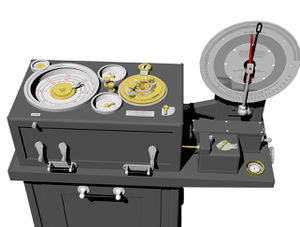

The Argo Clock was the heart of the system. It comprised knobs for entering in an initial range estimate and other estimated firing data, and then produced a continuously evolving set of parameters to track how the firing scenario changed over time. Indicators on the top panel gave a symbolic view of the range, bearing, inclination, and other factors, and output shafts permitted range and deflection to pass on to manual transmitters for communicating to director and guns.

The Argo Clock had a very well integrated design, and was nearly perfect in its implementation, with the notable exception that it was unable to track the target bearing when one's own ship was altering course. When this happened, the operator had to throw a switch and manually guesstimate the change in target bearing by use of a hand crank. This was attributable to limitations in how gyrocompass inputs were handled, and is an uncharacteristic "moustache" on an otherwise alluring visage of ballistic genius.

The Argo Clock as modeled here has a side-car on its right with a follow-the-pointer range transmitter on it. This was the means by which this vital data left the clock and ventured onward, ultimately to the director and the guns. Any such device was most useful when tied intimately into the other aspects of the ship's operation, and these transmitters were the sinews of such connectivity. Over time, fire control equipment of all nations would achieve an ever more complete level of integration and automation.

Argo equipment was never used in this configuration in action, a fact which is still the basis of debate and acrimony (see our "sources" page and reference the work of Prof. Jon Sumida and Mr. John Brooks). The debate has a personal and political dimension, but the most compelling aspect in our view is how did this system of fire control compare to that offered by the Dreyer Fire Control Table?

The Argo system, in my view, was undercut in overall value by its reliance on true-course plotting. Simply put, plotting the course in this manner solved no problems whatsoever, and seemed to be the basis for providing the expensive Argo Plotter. This device appears to have worked, but one must again wonder to what benefit? In addition to failing to decompose bearing and range information into a form where its derivatives could be rightly judged and its noise level assessed and managed accordingly -- a task achieved quite directly in the Dreyer system's range-vs-time and bearing-vs-time plotting, the Argo Plotter itself needed a single canonical source of bearings and ranges, and this was at odds with the need to filter out errors and noise in measuring these.

That said, the Argo system had a nearly perfect clock mechanism of highly automated design. It presented its data simply and in a compact display panel. Its variable speed drives for integrating range and bearing rates into a continually updated range and bearing could change their speed without slippage, allowing these parameters to be modeled smoothly where Dreyer clocks did so linearly. John Brooks has pointed out that since Dreyer clocks could be adjusted in discrete increments at a fairly high speed, this was of minor practical benefit, but its totally perfect provision in the Argo clock is the sort of hallmark that attended the designs and manufacturing of Arthur Pollen and his lead designer, Harold Isherwood.

45 Argo rangefinders were eventually delivered to the Royal Navy, typically taking place of honor in the armored sighting hood of a dreadnought or battlecruiser. A handful of Argo clocks found their way into a pragmatically synthetic design called the Dreyer Table Mark II, where it replaced the electrical dumaresq then being used in the most modern Dreyer tables but was able to pair its strengths and reliably smooth operation with the statistically more robust plotting methods of range and bearing versus time. This pairing was perhaps the zenith of fire control achieved in WW-I when viewed simply at the transmitting station level.

See Also

- Argo Plotter

- Argo Clock

- Dreyer Fire Control Table

- Ford Rangekeeper

- Admiralty Fire Control Table

- Le Prieur Fire Control Table

Footnotes

Bibliography